This video is a full 17 minutes of knowledge packed goodness to help you level up your fire performance. Many pro tips. Please be patient and watch, listen, and read the entire episode.

Fuel

[fusion_builder_container hundred_percent=”yes” overflow=”visible”][fusion_builder_row][fusion_builder_column type=”1_1″ background_position=”left top” background_color=”” border_size=”” border_color=”” border_style=”solid” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”no” center_content=”no” min_height=”none”]4.0 FUEL SAFETY, USE, AND RECLAMATION

4.1 Video Intro

Hello, welcome back to the Flow Arts Institute’s Fire Safety Video Series. My name is Dr. Howard Chen, and I’m the Director of Safety for the Flow Arts Institute. This video deals with the practical aspects of fuel safety, handling, use, and reclamation. Knowing what we’ve already learned about fuels from our previous video, let’s apply the principles to creating a safe environment for fuel storage and use.

4.2 Primary Fuel Storage

Firstly, in terms of Fuel Storage, the recommended, and most obvious strategy is to keep fuel in its original retail or shipping container. For example, Coleman (or Crown or Ozark Trail) Camp Fuel (otherwise known as White Gas or Naphtha) comes off the shelf in a plastic or tin plated (F-Style) steel container. Storing fuel in the factory container is recommended for several reasons – their contents are well marked, there are warning and first aid instructions on the can, and the containers are designed for long term storage of this exact fuel. Label the contents clearly, and return the fuel to the original shipping container once you’re done using it. If the returning fuel has been mixed, err on the side of storing it in the original shipping container of the most Flammable Liquid, usually the White Gas. Of course, store the fuel away from sources of heat or ignition.

4.3 Secondary Fuel Storage

For longer term storage of fuel, or for the storage of up to 60 gallons of fuel which will be used in the near future, we recommend not only that your fuels are stored in their original shipping or manufacturer’s container, but that they are additionally stored inside a locker rated for flammable liquids. The locker should be lockable, have the words “Flammable – Keep Fire Away” emblazoned on it, and have NFPA Hazard Rating sticker on the outside, with the most flammable fuel’s (Usually White Gas) Hazard Rating. It’s recommended that you have a large BC or ABC rated extinguisher next to the fuel locker. For more information, please refer to the NFPA 30 guidelines.

4.4 Containers for Immediate Fuel Use (.ie fuel dipping)

Well, we’ve just discussed primary and secondary fuel storage. Let’s turn our attention to the containers to use when we’re fueling our props. When you need to briefly pour fuel from the original retail or shipping container into another container for wick fueling purposes, the most appropriate dipping container is a 5 gallon or smaller metal container, preferably with a self closing lid. Ideally, according to NFPA 30, we’d be using a “safety can”, which is a single opening, self closing and self venting can, but unfortunately, none of the commercially available safety cans are appropriate for fueling props. So commonly, our community uses a clean, empty, tin-plated steel paint can with a tight fitting lid. Don’t forget to close the lid after you’re done fueling!

It’s important to put your dipping container into a “secondary containment basin”, which is a larger tub or pan useful for catching fuel drips and spills. If the secondary containment basin has a self closing or manual lid, so much the better.

4.5 Fuel Handling

Ok, now let’s talk about how to handle fire performance fuels safely.

As all hydrocarbon or alcohol based fuel that is absorbed, inhaled, or ingested has human toxicity, the use of personal protective equipment, such as solvent resistant gloves, apron, and eye protection is an important part of safe fuel handling. Generally, for handling fire performance fuels, personal protective equipment made of neoprene or nitrile give the best protection. Once you’ve finished handing the fuel, wash your hands and other exposed skin with soap and water.

As we talked about in our fuels chapter, any source of flame or spark can ignite fuel vapors that are released when fuel is being poured. The obvious sources of flame include lit cigarettes or the open flames of other performers. However, it’s important to remember that sparks may also created with handheld electronics such as our mobile phones, computers or tablets. Static electricity is another often overlooked cause of sparks, so be sure to ground yourself electrically by touching metal with your bare skin before handling fuel.

4.6 Ventilation

Aside from the skin toxicity and ignition potential of fuel handling, the breathing of hydrocarbon based fuel vapors and the byproducts of combustion is also dangerous to your health. As a result, it’s quite important to ensure adequate ventilation when handling and burning fuel. Generally, when performing outside, ventilation is usually adequate, although lack of wind or a partially enclosed space can change the adequacy of your ventilation.

On the other hand, inside practices or performances using hydrocarbon fuel and live fire can quickly overwhelm indoor ventilation systems. Please test the indoor venue’s ventilation system with a full scale lit practice run prior to any performance. If any fumes are detected, it’s important to have the venue do what it can to improve the ventilation during the performance for the health and safety of you, your team, and the audience.

Remember, one of the factors in keeping fuel vapors out of the air is keeping the exposed surface area of the fuel to a minimum. In real world terms, this means that keeping the fuel storage and dipping containers closed as often as possible is important in maintaining good air quality.

A question that is often asked is if there is a fuel that can be used indoors or in other low ventilation environments that doesn’t release fumes. Unfortunately, the answer is “No”. As long as we’re burning hydrocarbon or alcohol based fuel under conditions of incomplete combustion, toxic byproducts, such as carbon monoxide will always be produced.

4.7 Fuel Documentation to Have On Hand

For reference, and for emergency procedures, consider keeping copies of each fuel’s MSDS in your venue / gig binder. In addition, other relevant information may include your contract with the venue as well as a layout map of the performance and fueling areas.

4.8 How to Fuel (“Dip”) your fire performance props.

Let’s move on to the proper fueling of your fire practice and performance props. There are quite a few myths and lots of confusion about prop fueling, so in this section of the video, I’ll also address a few of the misconceptions.

First, let’s go over the goal of prop fueling. In general, the goal is to match the amount of fuel and the desired burn time. In many cases, the performer is trying to get the prop wick to absorb as much fuel as it can hold, for the longest possible burn time. In other cases, the performer is trying to fit a specific burn time requirement.

There are problems with over fueling or underfueling. Too much fuel will cause the excess fuel (which is often lit) to drip or fly off during prop manipulation. Not enough fuel also poses a problem – not only will your burn time be shorter than expected, but there is also a risk that your wick’s kevlar fibers will begin to smolder when the liquid fuel runs out, shortening their lifespan.

How do we balance the risks of overfueling versus underfueling? In general, a quick 1-2 second complete immersion of the wicks in fuel is all that’s needed. If the wicks are too large, pouring fuel on them over the dipping can works as well. The important thing is to make sure that all of the wick has been wetted with fuel. Resist the urge to let the wicks soak in the fuel for a longer period of time – remember, the fuel from a 1-2 second dip will make it’s way to the center of the wick through capillary action as well as centrifugal action when the prop is spun out, so you generally don’t have to worry about a dry inner wick when performing.

For those wicks that are difficult to fuel, consider using different sized dip cans or a short section of metal gutter.

There are two myths that i’d like to address:

1)The need to store your kevlar wicks in fuel. This was an old myth that purported that this practice would improve the lifespan of the wicks. However, a careful reading of the MSDS for Kevlar shows that it is quite stable in a dry environment. The danger of this myth is the long term effect of solvent fuel on the hardware of your props. The solvent fuels strip lubrication, warp wood, loosen screws and may degrade your prop handles and other non-metal components.

2) The need to “redip” your wicks to top off the fuel just prior to igniting them. It is true that your wicks fueled in white gas or alcohol will slowly dry out if they remain unlit over a period of time. However, re-dipping them is often unnecessary. Consider fueling your wicks, not spinning them out at the time of fueling, and then spinning the excess fuel off the wicks when you are about to ignite the wicks. Alternatively, it’s often practical to fuel, spin out, and then bag your wicks with zipper top plastic bags until they’re needed.

[/fusion_builder_column][fusion_builder_column type=”1_1″ background_position=”left top” background_color=”” border_size=”” border_color=”” border_style=”solid” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”no” center_content=”no” min_height=”none”][VIDEO – FUELING PROCESS]

To summarize – When fueling your wicks in your chosen liquid fuel, consider the following recommendations

- Dip and fully immerse the wicks BRIEFLY (1-2 seconds) in fuel

- Prevent handles/chain/shafts of the props from being immersed in fuel

- Drip the excess fuel back into the fuel dipping container or secondary fuel container

- Spin the excess fuel off into the designated fuel spin off area or spin off bag.

4.9 Spinoff Procedures / Fuel Reclamation

Let’s now talk about spinning off a prop, the process of removing excess fuel from the performance prop’s wicks. In general, we use the centrifugal force of the spinning (and unlit) prop to accomplish this and use a device or structure to catch the spun off fuel. The purpose of spinning off is to decrease the dangers of excess fuel, conserve fuel, and protect the environment.

The easiest and safest method of performing a spin off is the use of zip top freezer weight plastic food storage bags, which are large enough to zip around the prop wick for fuel collection. Once you’ve affixed the zip top bag, spin the prop in a circular motion until no more fuel fills the bag. Next, remove the bags from your wicks and simply pour the fuel back into your dipping can. Be aware that these plastic bags do degrade in solvent fuels, and are prone to leaking, and thus should be replaced often.

I strongly recommend against using a one gallon paint can to spin off your poi, as the handle isn’t meant to withstand the centrifugal forces generated by spinning the can. A can full of flying fuel can certainly be dangerous!

At the Flow Arts Institute, we’ve developed portable, environmentally friendly fuel spinoff and reclamation structures for large events. While the construction and maintenance of these fuel stations is the subject of a future instructional video from the Flow Arts Institute here are a few of the pictures of various fuel dipping and fuel spinoff structures from Fire and Flow festivals across the county.

An alternate spinoff method which can be used when fuel spin off bags are not available, is squeezing the wicks with a gloved hand above your dip can. For this, I recommend the use of single use, disposable nitrile gloves. Heavier, multi-use fluid resistant gloves can also be used, but in a performance environment with multiple hands using them, they often get contaminated with fuel on the insides of the gloves.

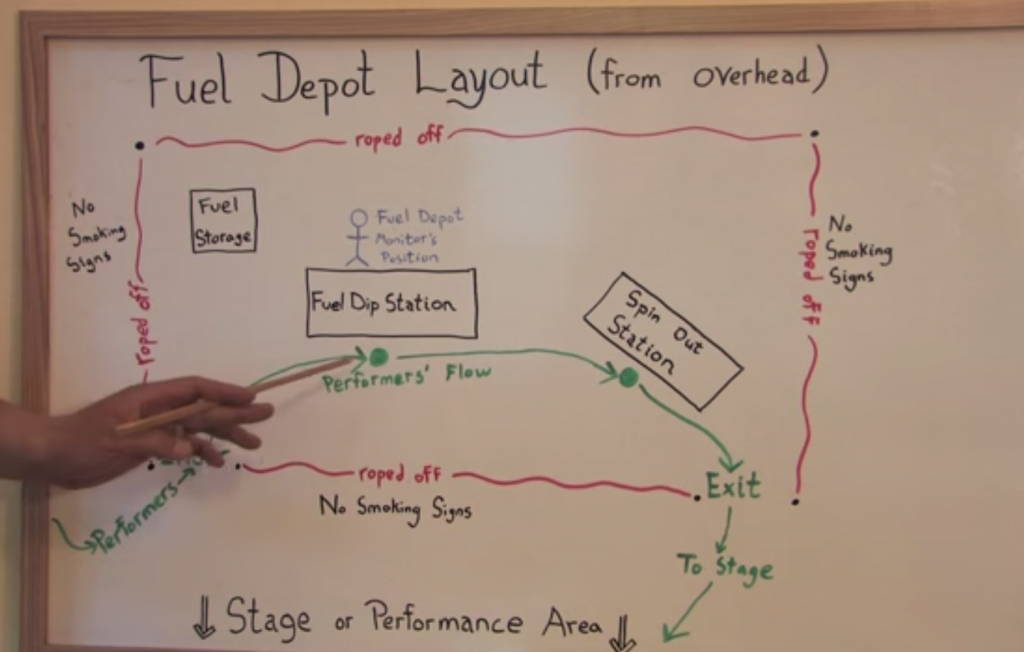

4.10 Fuel Depot Placement

In general, the fuel depot should be placed as far away as possible from sources of ignition, such as open flames or heat sources. Additionally, it should be placed in a well ventilated area. The fuel depot should not be located in the direct “line of fire” from the performance area or stage, but however, the fuel depot does need to be placed in some semblance of proximity to the fire performance or practice area, so that it is convenient to dip and spin off fuel. Having a physical barrier between the fuel depot and the live fire is preferred, but if this is not possible, consider orienting the fuel depot such that the fuel depot monitors can have a clear view of the dangers which may be coming their way.

4.11 Fuel Depot Layout

The layout of the fuel depot should be designed for ease of access. I recommend a separate entry and exit for performers so as to decrease congestion within the depot. If possible, the main fuel dipping area should face the performance area, so that the fuel depot personnel can monitor for incoming fire. The spinoff area should be located adjacent to the dipping area, just inside of the boundaries of the fuel depot, but far enough away to prevent fuel depot personnel or performers from being sprayed with spun- off fuel. The Fuel depot should be well lit with lights located at a safe distance from the fueling area. The fuel depot should have appropriate signage warning of the flammability of the contents. Specifically, there should be several “no-smoking” signs, as well as a warning sign which states “Flammable, Keep Fire Away” on the fuel storage locker.

4.13 Video Summary

Well, that’s about it for this video on the Fuel storage, use, conservation, and reclamation. Before we end, I’d like to summarize some of the points we covered that I think are important. 1) Store fuel in it’s original shipping container. 2) If you’ve got more than just a few cans, store the fuel in it’s original shipping container inside of a locker rated for flammable liquids. 3) Because fuel, it’s vapors, and it’s products of combustion are toxic to the skin and multiple organs of the body, it’s important to wear personal protective equipment such as fluid resistant gloves, apron and eye protection when handling fuel, as well as being aware of ventilation issues. 4) There are safe, environmentally friendly ways to accomplish fuel spin off, including using plastic zip top bags, spin off structures, and hand squeezing. 5) Finally, in terms of the fuel depot, there are several considerations regarding location and organization which help to improve safety.

There are certainly many more questions about fuel storage and dispensing that I haven’t had the time to address in this video. For those, please refer to the NFPA #30 – you can find the weblink on the Flow Arts Institute website.

4.14 Video End

Thanks again for tuning into the Flow Arts Institute’s video series of Fire and Fuel safety for Fire Performers and Fire Safety Personnel. For more information about the fire retardant properties of various fabrics, please tune into our next video! I’m Dr. Howard Chen, for the Flow Arts Institute. [/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

Comments 2

Hello,

I’m wondering if you have any recommendations for disposing of excess fuel after use in an environmentally friendly way. Thank you!

Wondering about cleaning tin cans and funnel used in dipping. Lost the lid for my dipping can and want to clean it as to not store it unsafely.